Asu Air Separation Plant Oxygen Plant

Basic Info

Model No.: KDON1500Y

Product Description

Model NO.: KDON1500Y

Air Separation: Cryogenic

Origin: Shanghai

Gas Source: Gas

Trademark: SEF

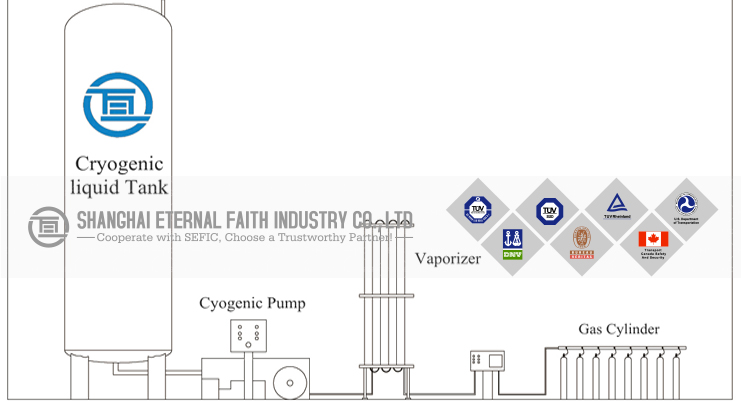

An Air Separation Plant separates atmospheric air into its primary components,

Typically nitrogen and oxygen, and sometimes also argon and other rare inert

The Asu Plant produce Liquid Gas as the following Seven Steps:

1 Before compression the air is pre-filtered of dust.

2 Air is compressed where the final delivery pressure is determined by recoveries and the

Fluid state (gas or liquid) of the products. Typical pressures range between 5 and 10 bar gauge.

The air stream may also be compressed to different pressures to enhance the efficiency of the

ASU. During compression water is condensed out in inter-stage coolers.

3 The process air is generally passed through a molecular sieve bed, which removes any

Remaining water vapour, as well as carbon dioxide, which would freeze and plug the cryogenic

Equipment. Molecular sieves are often designed to remove any gaseous hydrocarbons from

The air, since these can be a problem in the subsequent air distillation that could lead to

Explosions. The molecular sieves bed must be regenerated. This is done by installing multiple

Units operating in alternating mode and using the dry coproduced waste gas to desorb the water.

4 Process air is passed through an integrated heat exchanger (usually a plate fin heat exchanger)

And cooled against product (and waste) cryogenic streams. Part of the air liquefies to form a

Liquid that is enriched in oxygen. The remaining gas is richer in nitrogen and is distilled to

Almost pure nitrogen (typically < 1ppm) in a high pressure (HP) distillation column. The

Condenser of this column requires refrigeration which is obtained from expanding the more

Oxygen rich stream further across a valve or through an Expander, (a reverse compressor).

5 Alternatively the condenser may be cooled by interchanging heat with a re boiler in a low

Pressure (LP) distillation column (operating at 1.21.3 bar abs. ) when the ASU is producing

Pure oxygen. To minimize the compression cost the combined condenser/reboiler of the

HP/LP columns must operate with a temperature difference of only 1-2 degrees Kelvin, requiring plate fin brazed aluminum heat exchangers. Typical oxygen

Purities range in from 97.5% to 99.5% and influences the maximum recovery of oxygen.

The refrigeration required for producing liquid products is obtained using the JT effect in an

Expander which feeds compressed air directly to the low pressure column. Hence, a certain

Part of the air is not to be separated and must leave the low pressure column as a waste stream

From its upper section.

6 Because the boiling point of argon (87.3 K at standard conditions) lies between that

Of oxygen (90.2 K) and nitrogen (77.4 K), argon builds up in the lower section of the low

Pressure column. When argon is produced, a vapor side draw is taken from the low pressure

Column where the argon concentration is highest. It is sent to another column rectifying the

Argon to the desired purity from which liquid is returned to the same location in the LP column.

Use of modern structured packings which have very low pressure drops enable argon purities

Of less than 1 ppm. Though argon is present in less to 1% of the incoming, the air argon column

Requires a significant amount of energy due to the high reflux ratio required (about 30) in the

Argon column. Cooling of the argon column can be supplied from cold expanded rich liquid or

By liquid nitrogen.

7 Finally the products produced in gas form are warmed against the incoming air to ambient

Temperatures. This requires a carefully crafted heat integration that must allow for robustness

Against disturbances (due to switch over of the molecular sieve beds). It may also require

Additional external refrigeration during start-up.

| AIR SEPARATION PLANT SPECIFICATIOIN TABLE | ||||||||

| MODEL CONTENTS | KDON-200Y/200Y | KDON-500Y/500Y | KDON-1000Y/1000Y | KDON-1500Y/1500Y | KDON-2000Y/2000Y | KDON-3000Y/3000Y | KDON-4500Y/2000Y | |

| *LOX flow | Nm3/h | 200 | 500 | 1000 | 1500 | 2000 | 3000 | 4500 |

| LOX purity | %(O2) | 99.6 | 99.6 | 99.6 | 99.6 | 99.6 | 99.6 | 99.6 |

| *LIN flow | Nm3/h | 200 | 500 | 1000 | 1500 | 2000 | 3000 | 2000 |

| LIN purity | %(N2) | 99.999 | 99.999 | 99.999 | 99.999 | 99.999 | 99.999 | 99.999 |

| *LAr flow | Nm3/h | - | - | 25 | 40 | 55 | 95 | 145 |

| LAr flow | %(Ar) | - | - | 99.999 | 99.999 | 99.999 | 99.999 | 99.999 |

| Star-up time | (h) | 8~12 | ~20 | ~24 | ~24 | ~24 | ~24 | ~24 |

| Operating period | (Y) | ≥1 | ≥1 | ≥2 | ≥2 | ≥2 | ≥2 | ≥2 |

Contact us if you need more details on Air Separation Plant. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Oxygen Generation Plant、Argon Generation Plant. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Asu Plant

Other Products

Hot Products

2015 New ISO Standard T50 Transport Tank ContainerISO Standard Asme Certification T75 Tank ContainerLNG Lin Lox Lar Industrial Ambient Vaporizer (SEFIC-400-250)Tempered Glass Vented Exhaust Hood/Cooker Hood for Kitchen Appliance/Range HoodLow Water Pressure Flue Type Instant Gas Water Heater2014 High Pressure Seamless Aluminum Oxygen Gas Cylinder (LWH180-10-15)Qf Cga Oxygen Nitrogen Argon Gas Cylinder Valve2 Burners 710 Length Stainless Steel Built-in Hob/Gas Hob50L High Pressure Seamless Steel Oxygen Gas CylinderImo7/ T 75 Tank ContainerAsu Air Separation Plant Oxygen Plant3 Burners Stainless Steel 710mm Length 100 Iron Steel Cap Gas Cooker/Gas Stove3 Burners Nonstick 710mm Length Honeycomb Gas Cooker/Gas Stove40L/6m3 Oxygen Cylinder2 Burners Tempered Glass Top 100#Aluminum Burner Gas Cooker/Gas Stove2 Burners Tempered Glass Top Brass 120mm Brass Burner Cooker/Gas Stove